===

Repairing and overhauling Tigercat heavy equipment engines is a complex task that requires expertise and precision. To ensure the best possible outcome, it is crucial to follow the manufacturer’s guidance throughout the repair and maintenance process. Tigercat, a renowned manufacturer of heavy equipment, provides comprehensive manuals and guidelines to assist technicians in performing engine repairs. By adhering to these guidelines, technicians can ensure the longevity and optimal performance of Tigercat heavy equipment engines.

The Importance of Manufacturer’s Guidance in Repairing Tigercat Heavy Equipment Engines

When it comes to repairing Tigercat heavy equipment engines, following the manufacturer’s guidance is of utmost importance. These guidelines are specifically designed to address the unique characteristics and requirements of Tigercat engines. They provide detailed instructions on disassembling, inspecting, cleaning, repairing, and reassembling each component of the engine. By following these guidelines, technicians can minimize the risk of errors and ensure that the engine is repaired correctly the first time.

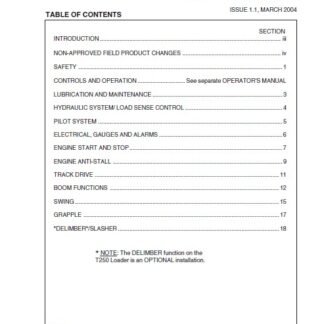

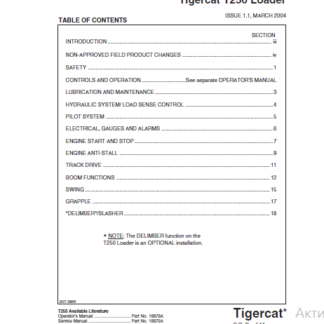

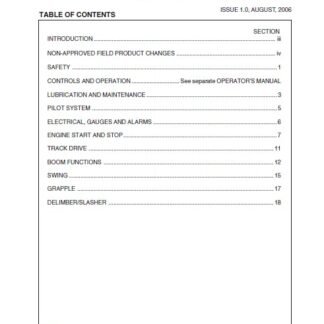

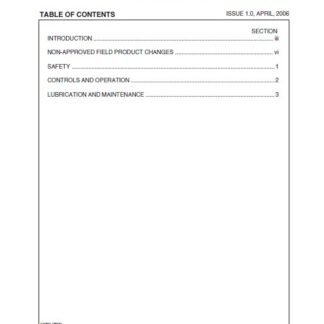

Tigercat’s manuals are easily accessible online at https://tigercat-manual.com. These manuals contain step-by-step instructions, diagrams, and illustrations that aid technicians in understanding the intricate workings of Tigercat heavy equipment engines. The manuals also provide valuable information on the recommended tools, equipment, and techniques for each repair procedure. By consulting these manuals, technicians can confidently navigate through the repair process, ensuring a successful outcome.

Essential Steps for Overhauling Tigercat Heavy Equipment Engines

Overhauling Tigercat heavy equipment engines involves a series of essential steps that must be followed meticulously. These steps include disassembling the engine, inspecting and measuring each component, cleaning and repairing or replacing worn parts, reassembling the engine, and conducting thorough testing to ensure its proper functioning.

Tigercat’s manuals provide detailed instructions for each step of the overhaul process. They outline the specific tools and equipment required, as well as the recommended techniques for disassembly and reassembly. Following these instructions is crucial to avoid any damage to the engine and to ensure that all parts are properly installed and aligned.

Advantages of Following Manufacturer’s Guidelines in Tigercat Heavy Equipment Engine Repair

Following the manufacturer’s guidelines in Tigercat heavy equipment engine repair offers numerous advantages. Firstly, it ensures that the repair is carried out in accordance with the manufacturer’s specifications, maintaining the integrity and reliability of the engine. Secondly, it helps technicians identify and address potential issues that may not be apparent without proper guidance. By following the guidelines, technicians can detect and rectify any underlying problems, thereby preventing future breakdowns and costly repairs.

Moreover, adhering to the manufacturer’s guidelines ensures that the warranty of the Tigercat heavy equipment engine remains valid. Deviating from these guidelines may void the warranty, leaving the repair costs solely on the technician or equipment owner. By following the guidelines, technicians can ensure that the engine remains under warranty, protecting their investment.

Ensuring Optimal Performance: Tigercat Heavy Equipment Engine Repair Techniques

To ensure optimal performance, it is essential to employ the right repair techniques when working on Tigercat heavy equipment engines. Tigercat’s manuals provide technicians with detailed instructions on the correct procedures for inspecting, cleaning, and repairing various engine components. By following these techniques, technicians can restore the engine to its original condition and maximize its efficiency.

Additionally, the manuals offer valuable insights into preventive maintenance practices that can extend the lifespan of Tigercat heavy equipment engines. These practices include regular oil and filter changes, proper lubrication, and scheduled inspections. By implementing these maintenance techniques, technicians can prevent major issues and keep the engine running smoothly.

===

Repairing and overhauling Tigercat heavy equipment engines is a task that should not be taken lightly. By following the manufacturer’s guidance provided in Tigercat’s comprehensive manuals, technicians can ensure that the repair process is carried out with precision and efficiency. The availability of these manuals online at https://tigercat-manual.com makes them easily accessible to technicians worldwide. By adhering to the manufacturer’s guidelines, technicians can guarantee the optimal performance and longevity of Tigercat heavy equipment engines.