===

Tigercat is a renowned manufacturer of heavy equipment used in the forestry and construction industries. Their commitment to providing exceptional service to their customers is evident in the inclusion of schematics and wiring diagrams in their service manual. This comprehensive manual serves as a vital resource for equipment owners and technicians, offering invaluable information for maintenance and troubleshooting. In this article, we will delve into the importance of schematics and wiring diagrams in the Tigercat Heavy Equipment service manual and explore how it enhances equipment maintenance.

Understanding the importance of schematics in the manual

Schematics play a crucial role in the Tigercat Heavy Equipment service manual. These detailed diagrams provide a visual representation of the various systems and components within the equipment. By understanding the layout and connections of these components, technicians can quickly identify potential issues and troubleshoot effectively. Schematics also aid in the proper assembly and disassembly of parts during maintenance or repairs, ensuring that everything is correctly installed. With the help of these schematics, technicians can save time and effort, ultimately leading to more efficient equipment servicing.

Comprehensive wiring diagrams for troubleshooting

Wiring diagrams are another essential component of the Tigercat Heavy Equipment service manual. These diagrams illustrate the electrical connections between different components and systems within the equipment. In case of electrical malfunctions or faults, these diagrams serve as a roadmap for technicians to trace and identify the source of the problem. This level of detail ensures that troubleshooting is carried out accurately, reducing the risk of misdiagnosis and unnecessary repairs. The comprehensive wiring diagrams included in the Tigercat service manual provide technicians with the necessary information to resolve electrical issues swiftly.

How Tigercat’s service manual enhances equipment maintenance

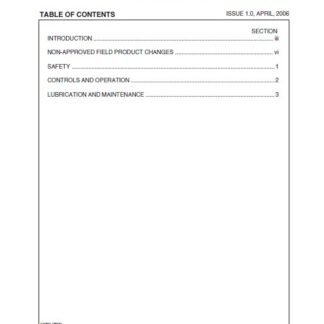

The Tigercat Heavy Equipment service manual is a valuable resource that enhances equipment maintenance in several ways. Firstly, it provides detailed instructions and guidelines for routine maintenance tasks, such as lubrication, filter replacements, and inspections. This ensures that equipment owners can perform essential maintenance activities themselves, reducing downtime and minimizing the need for external assistance. Additionally, the service manual includes recommended maintenance schedules, helping owners stay on top of their equipment’s maintenance needs.

Furthermore, the service manual covers troubleshooting procedures for various common issues that may arise during the operation of Tigercat heavy equipment. With step-by-step instructions and diagnostic flowcharts, technicians can quickly identify the root cause of a problem and implement the appropriate repairs. This reduces equipment downtime and ensures optimal performance.

In conclusion, the inclusion of schematics and wiring diagrams in the Tigercat Heavy Equipment service manual is a testament to the company’s commitment to customer satisfaction. These resources provide technicians with the necessary tools to efficiently diagnose and repair equipment issues. By empowering owners and technicians with comprehensive information, Tigercat enables them to conduct routine maintenance and troubleshoot effectively, ultimately optimizing the performance and longevity of their heavy equipment.

===

To access the Tigercat Heavy Equipment service manual and benefit from the comprehensive schematics and wiring diagrams, visit tigercat-manual.com. Whether you are an equipment owner or a technician, this invaluable resource will undoubtedly enhance your equipment maintenance practices.