In the modern age of machinery maintenance and repair, having access to reliable resources is crucial for ensuring operational efficiency and longevity. Tigercat, a leader in the design and manufacturing of premium forestry and off-road industrial equipment, understands this necessity. The online Tigercat repair manual, accessible directly from the manufacturer, provides an indispensable resource for technicians and operators. This article delves into the importance, navigation, features, and benefits of this comprehensive manual, highlighting why it is a necessity for anyone involved in maintaining Tigercat equipment.

Understanding the Tigercat Repair Manual’s Importance

The Tigercat repair manual is a critical tool for ensuring that machinery operates smoothly and efficiently. As equipment becomes more complex, understanding the intricacies of each component is paramount. The manual serves as a detailed guide, offering step-by-step instructions and insights into the machinery’s inner workings. This is particularly important for technicians who need to troubleshoot and resolve issues swiftly to minimize downtime and maintain productivity.

Moreover, the repair manual is essential for maintaining the safety and reliability of Tigercat machinery. By following the manufacturer’s recommended procedures and guidelines, operators can ensure that repairs and maintenance tasks are performed correctly. This not only extends the lifespan of the equipment but also prevents hazardous situations that could arise from improper handling or repair work. In industries where safety is paramount, such as forestry, adhering to these guidelines is non-negotiable.

The repair manual also plays a vital role in preserving the warranty of Tigercat equipment. Manufacturers often stipulate that only approved procedures and parts be used during repairs to maintain the validity of the warranty. By using the official online repair manual, technicians can ensure that they are in compliance with these requirements, protecting the investment made in the machinery.

In addition to its practical applications, the manual serves as an educational tool for operators and technicians. Understanding the functionality and repair processes of Tigercat equipment can enhance the skills and knowledge of the workforce, leading to improved efficiency and problem-solving capabilities. This investment in understanding the machinery can yield significant returns in terms of reduced repair costs and increased equipment uptime.

Navigating the Online Tigercat Repair Manual

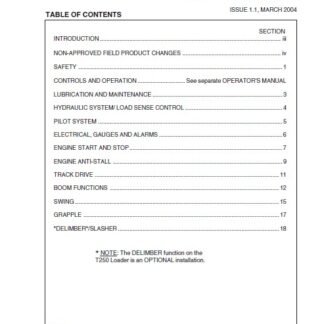

Navigating the online Tigercat repair manual is designed to be user-friendly and intuitive, ensuring that users can quickly find the information they need. The digital format allows for easy searching and cross-referencing, making it simple to locate specific sections or topics. This ease of navigation is crucial for technicians who need to access information rapidly while working on urgent repairs.

The online platform is structured to accommodate both novice and experienced users. It includes a comprehensive table of contents and index, allowing users to jump directly to the section they need. Additionally, the manual is organized in a logical manner, with sections dedicated to different components and aspects of the machinery. This structured approach helps users systematically approach repairs and maintenance tasks.

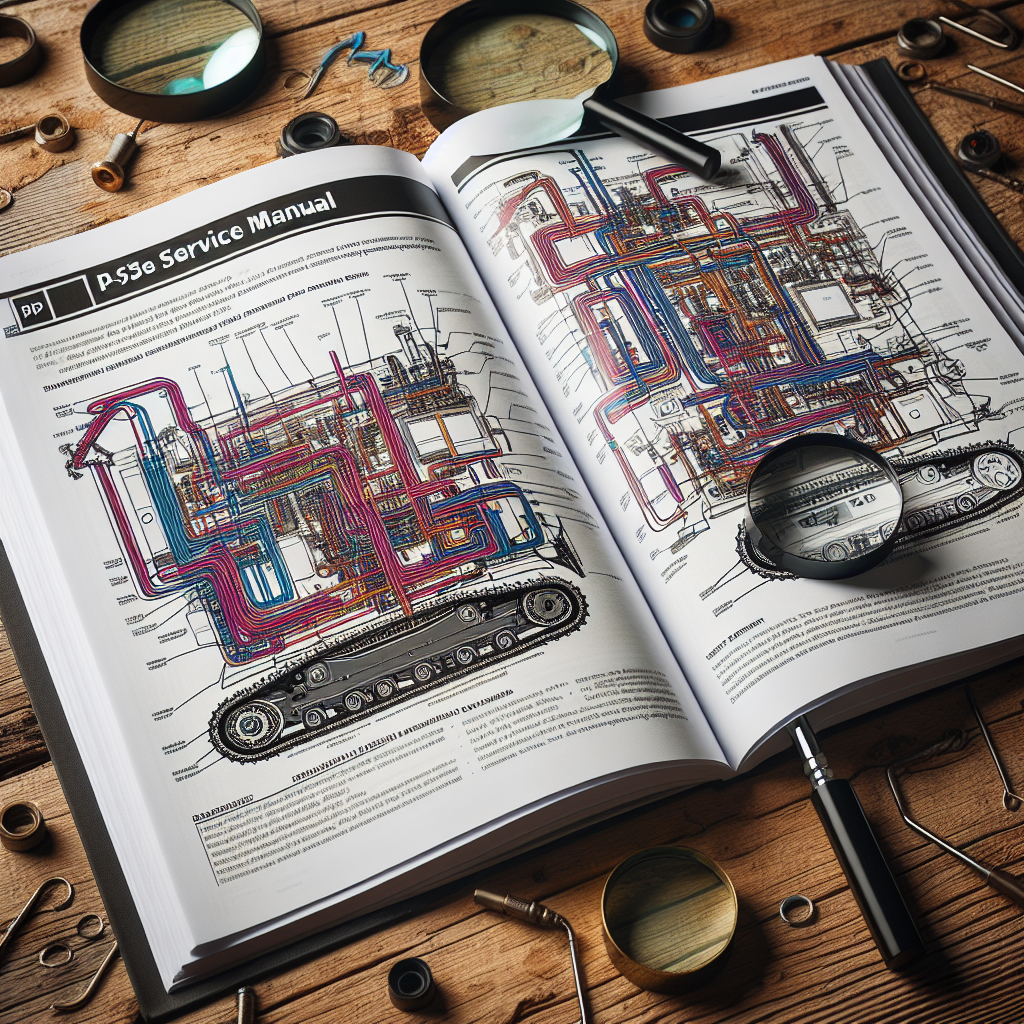

Interactive elements, such as diagrams and videos, enhance the usability of the online manual. These visual aids provide clear, step-by-step guidance, making complex procedures easier to understand and execute. For technicians who are visual learners, these resources are invaluable, providing clarity and reducing the likelihood of errors during repairs.

Accessing the manual online also ensures that users are always working with the most up-to-date information. Manufacturers regularly update repair manuals to reflect changes in technology and best practices. By utilizing the online version, users can be confident that they are following the latest guidelines and recommendations from Tigercat, ensuring optimal performance and compliance.

Key Features of the Tigercat Repair Manual Online

The online Tigercat repair manual boasts several key features that make it an indispensable resource for equipment maintenance. One of its standout features is the comprehensive range of information covered. From routine maintenance tasks to complex repair procedures, the manual provides detailed instructions and specifications for every aspect of Tigercat machinery.

Detailed schematics and diagrams are another critical feature of the online manual. These visual tools provide a clear representation of the equipment’s components and their interconnections. Technicians can use these diagrams to accurately diagnose issues and understand the correct assembly and disassembly processes, ensuring precision in repairs.

Another notable feature is the inclusion of troubleshooting guides. These guides help technicians identify and resolve common issues efficiently, minimizing downtime and the need for trial-and-error approaches. By following these guides, users can systematically address problems, enhancing the effectiveness of repair efforts and reducing the likelihood of recurring issues.

The online manual also offers interactive support features, such as links to additional resources and contact information for manufacturer support. This connectivity ensures that users can seek further assistance if needed, whether that involves clarifying specific instructions or ordering replacement parts. This direct link to the manufacturer enhances the reliability and comprehensiveness of the repair manual.

Benefits of Direct Access to Manufacturer Resources

Having direct access to the manufacturer’s resources through the online Tigercat repair manual provides numerous benefits. First and foremost, it ensures that users are receiving accurate and authoritative information from the source. This is crucial for maintaining the integrity and performance of the equipment, as third-party resources may contain outdated or incorrect information.

Direct access also facilitates a more streamlined maintenance process. With the manufacturer’s resources at their fingertips, technicians can quickly verify specifications, procedures, and part numbers, reducing the time spent searching for information. This efficiency translates to faster repair times and reduced equipment downtime, ultimately benefiting the bottom line.

Furthermore, direct access to manufacturer resources fosters a stronger relationship between the user and Tigercat. By utilizing the official repair manual, users demonstrate their commitment to following the manufacturer’s guidelines and recommendations. This can lead to better support and service from Tigercat, as the company is more likely to provide assistance to users who adhere to its standards.

Lastly, having direct access to the online repair manual enhances the overall maintenance strategy for Tigercat equipment. By integrating this resource into regular maintenance routines, users can ensure that their machinery remains in peak condition, reducing the likelihood of unexpected breakdowns and costly repairs. This proactive approach to maintenance not only extends the lifespan of the equipment but also maximizes its productivity and efficiency.

In conclusion, the online Tigercat repair manual from the manufacturer is a necessity for anyone involved in the maintenance and repair of Tigercat machinery. Its importance lies in its ability to provide accurate, up-to-date information that ensures the safety, reliability, and efficiency of the equipment. By offering a user-friendly and comprehensive resource, Tigercat empowers technicians and operators to perform repairs and maintenance with confidence and precision. The benefits of direct access to manufacturer resources cannot be overstated, as they enhance the overall maintenance strategy and foster a stronger relationship with Tigercat. For more information and to access the manual, visit tigercat-manual.com.