Tigercat engines are renowned for their reliability, power, and efficiency. However, like any machine, they require regular maintenance and repairs in order to keep them running at peak performance. Repairing and overhauling Tigercat engines requires manufacturers guidance to ensure the job is done properly and safely. This article will provide an overview of the repair and overhaul requirements, the manufacturer’s guidelines for repairs, the necessary tools and equipment, and the step-by-step repair process.

Introduction to Tigercat Engines

Tigercat engines are powerful and efficient machines used in a variety of applications including logging, construction, and mining. They are renowned for their reliability, power, and fuel efficiency. They are also highly customizable, allowing for a wide range of configurations and performance levels.

Overview of Repair and Overhaul Requirements

Repairing and overhauling Tigercat engines requires a thorough understanding of the engine and its components. The engine must be disassembled and examined for any signs of wear or damage. All parts must be inspected and replaced if necessary. The engine must then be reassembled and tested for proper operation.

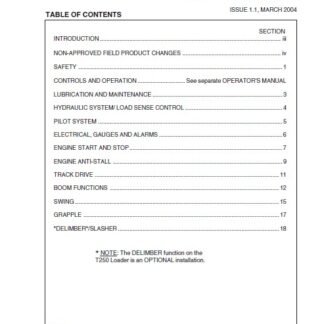

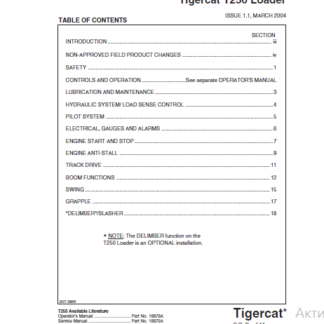

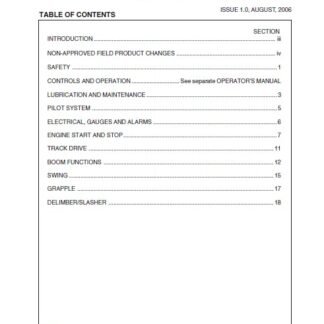

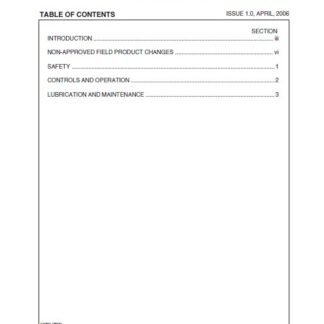

Manufacturer’s Guidelines for Repairs

Repairing and overhauling Tigercat engines requires following the manufacturer’s guidelines for repairs. The manufacturer’s guidelines can be found in the Tigercat service manual, which is available from the manufacturer or online at https://tigercat-manual.com. The service manual provides detailed instructions for repair and overhaul, including the necessary tools and equipment, the step-by-step repair process, and safety precautions.

Necessary Tools and Equipment

Repairing and overhauling Tigercat engines requires a variety of tools and equipment, including wrenches, screwdrivers, pliers, and torque wrenches. Other tools and equipment may also be required, depending on the type of repair being performed. All tools and equipment should be in good condition and appropriate for the job.

Step-by-Step Repair Process

The step-by-step repair process for Tigercat engines involves disassembling the engine, inspecting all parts, replacing any worn or damaged parts, and reassembling the engine. The service manual provides detailed instructions for each step of the repair process, including safety precautions.

Final Considerations

When repairing and overhauling Tigercat engines, it is important to follow the manufacturer’s guidelines and use the appropriate tools and equipment. Safety should always be the top priority, and all repairs should be done in accordance with the manufacturer’s instructions.

Repairing and overhauling Tigercat engines requires following the manufacturer’s guidelines and using the appropriate tools and equipment. The service manual, available from the manufacturer or online at https://tigercat-manual.com, provides detailed instructions for repair and overhaul, including the necessary tools and equipment, the step-by-step repair process, and safety precautions. With the right knowledge and resources, Tigercat engines can be repaired and overhauled safely and effectively.