In the world of heavy machinery, the importance of having comprehensive and reliable documentation cannot be overstated. For those who own or operate Tigercat equipment, the Factory Service Manual (FSM) is an invaluable resource. This detailed manual is designed specifically for Tigercat machinery, providing essential information for maintenance, troubleshooting, and repair. In this article, we will delve into the role of the FSM, explore its key features, understand how it supports machinery maintenance, and learn how to access and utilize it effectively.

Understanding the Role of the FSM in Tigercat

The Factory Service Manual (FSM) plays a crucial role in the maintenance and repair of Tigercat machinery. It is the definitive guide that provides detailed instructions and information necessary for servicing these complex machines. Designed by the manufacturer, the FSM contains technical specifications, diagrams, and step-by-step procedures that are vital for ensuring the equipment operates at peak efficiency. For technicians and operators, it serves as a reference point, offering insights into the intricacies of the machinery.

One of the primary roles of the FSM is to standardize maintenance procedures across all Tigercat equipment. This ensures that every machine is serviced in accordance with the manufacturer’s guidelines, maintaining consistency and quality. By following the FSM, operators can be confident that they are performing maintenance tasks correctly, thereby reducing the risk of errors that could lead to equipment failure or safety hazards.

Additionally, the FSM aids in troubleshooting by providing detailed diagnostic information. When a machine encounters issues, the manual offers guidance on identifying and resolving problems, often including flowcharts and diagnostic codes. This helps in minimizing downtime and ensures that the machinery is back in operation as quickly as possible.

The FSM also plays a role in training new technicians. By studying the manual, new hires can familiarize themselves with the machinery and learn the correct procedures for maintenance and repair. This not only enhances their skill set but also contributes to the overall efficiency and safety of the operation.

Key Features of the Tigercat Factory Service Manual

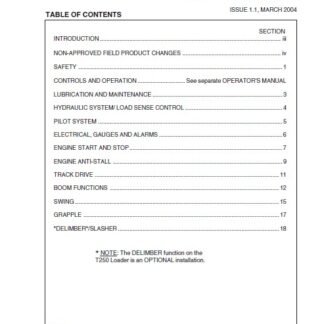

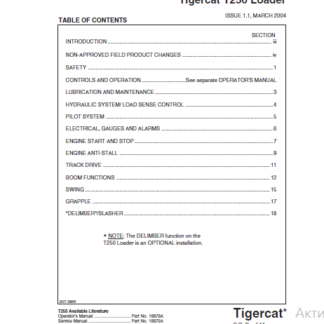

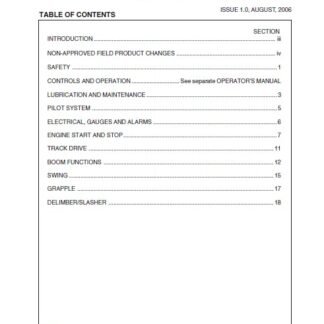

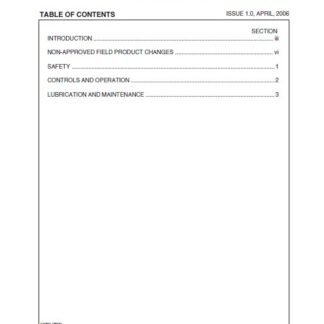

The Tigercat FSM is rich with features that make it an indispensable tool for anyone involved in the maintenance and repair of Tigercat machinery. One of its standout features is the comprehensive coverage of all machine components and systems. From hydraulic systems to electrical circuits, the FSM provides detailed information on every aspect of the equipment, ensuring no stone is left unturned when it comes to servicing.

Another key feature is the inclusion of detailed diagrams and illustrations. These visual aids are crucial for understanding complex systems and components, making it easier for technicians to follow instructions and perform tasks accurately. The diagrams often include exploded views that show the relationship between different parts, aiding in both assembly and disassembly processes.

The FSM also boasts an extensive troubleshooting section. This section is designed to help technicians quickly diagnose and fix problems, reducing machine downtime. It includes common issues, possible causes, and recommended solutions, as well as diagnostic codes and flowcharts that streamline the troubleshooting process.

Finally, the FSM features a maintenance schedule that provides guidelines on routine checks and servicing intervals. This helps ensure that all necessary maintenance tasks are performed on time, prolonging the lifespan of the machinery and preventing unexpected breakdowns. By adhering to the recommended schedule, operators can maintain optimal performance and reliability.

How the FSM Supports Tigercat Machinery Maintenance

The FSM is a cornerstone of effective maintenance for Tigercat machinery. It provides detailed maintenance procedures that ensure each task is performed correctly and efficiently. By following the FSM, technicians can carry out regular maintenance tasks with precision, reducing the likelihood of errors that could lead to costly repairs or safety issues.

Moreover, the FSM supports predictive maintenance by offering insights into wear patterns and common failure points. This information allows operators to anticipate potential issues and address them before they escalate, minimizing downtime and extending the life of the equipment. By utilizing the FSM, operators can implement a proactive maintenance strategy that keeps their machinery in top condition.

The manual also aids in parts replacement and inventory management. It provides detailed parts lists and specifications, which are essential for ordering the correct components. This ensures that replacements are compatible and of high quality, preventing further issues down the line. The FSM helps streamline the parts ordering process, reducing lead times and ensuring that necessary components are always on hand.

Additionally, the FSM is a valuable training resource for maintenance personnel. It provides a structured learning path that enhances technicians’ understanding of the machinery and its maintenance requirements. By familiarizing themselves with the FSM, technicians can improve their skills and contribute to a more efficient maintenance operation.

Accessing and Utilizing the FSM for Optimal Results

Accessing the Tigercat FSM is straightforward, thanks to resources like Tigercat Manual. This platform offers digital access to the FSM, making it easy for operators and technicians to obtain the information they need quickly. By having the manual readily available, users can ensure that they are always prepared to address any maintenance or repair tasks.

Utilizing the FSM effectively involves more than just reading the manual. Technicians should integrate the FSM into their daily routines, using it as a constant reference point. By doing so, they can ensure that all maintenance and repair tasks are performed to the highest standards, in line with the manufacturer’s recommendations.

For optimal results, it is essential to keep the FSM updated. As Tigercat releases new models or updates existing ones, the FSM may be revised to reflect these changes. By regularly checking for updates and ensuring that they are using the latest version, operators can maintain the accuracy and relevance of the information they rely on.

Finally, collaboration and communication are key when utilizing the FSM. Technicians should share insights and experiences with their peers, discussing any challenges or solutions they encounter. This collaborative approach fosters a culture of continuous learning and improvement, ultimately leading to better maintenance outcomes and enhanced machinery performance.

In conclusion, the Factory Service Manual is an essential tool for anyone involved in the operation and maintenance of Tigercat machinery. Its comprehensive coverage, detailed features, and role in supporting maintenance practices make it an invaluable resource. By understanding and utilizing the FSM effectively, operators and technicians can ensure the longevity and reliability of their equipment, ultimately contributing to the success of their operations. For more information and access to the FSM, visit Tigercat Manual.